How to build a lapstrake boat that never leaks

Jun 03, 2021When wood gets wet it swells up and when it dries, it shrinks. That's the basic mechanism behind the good old "leaky wooden boat" problem.

Wood swelling and drying

The joint between two planks may be a perfect fit when the boat is built. Then the boat goes into the water, the wood swells and the joint gets even tighter. Good, right?

Yes, but when the boat goes on land for winter storage and dries out, the wood often shrinks to a point beyond when it was built. The wood has been compressed when it swelled up, so when it dries out, tiny gaps can often be seen between the planks. There's your leaky boat.

The traditional way of solving this would be to leave the boat in the water all season long so that it doesn't dry out. And accept the fact that the boat will be leaky the first few days it spends in the water at the beginning of each season.

If the boat has just got a fresh coat of spring paint, some of it might have crept into the crack. Perhaps sealing the gap or perhaps just keeping it from closing properly when the wood swells up again.

Which is leakier: Lapstrake or carvel?

Because the planks of lapstrake boats overlap, I find that there is generally less of a problem with leaks due to drying: With overlapping planks, only the swelling and drying in thickness of the planks can create leaks. With carvel (smooth) planking, the shrinking and swelling in width of the planks create the leaks. The width of two planks, obviously, is much greater than the thickness of two planks, thereby creating more shrinking and swelling - and potentially bigger leaks. This is one of the reasons why carvel boats are caulked with cotton or oakum in the plank seams, but this caulking does not necessarily keep up with the drying and swelling cycles.

The Harry Bryan/Walter Simmons trick for keeping lapstrake boats dry

While a lot of things surely were better in the old days, I do believe that Progress has actually brought a few useful things to boatbuilding. One of them is flexible glues and sealants.

But they are messy, and they stick to everything (including beards, children, and other things that you don't want it to stick to). So they need to be handled with care.

While you could caulk all joints in a traditionally built boat with a flexible sealant, it would probably be quite messy, and (because the sealant also acts a glue) it would probably make any repairs quite difficult.

I first learned about the following trick for keeping the seams of a lapstrake boat watertight from Harry Bryan, who in turn credits boatbuilder Walter Simmons for inventing it.

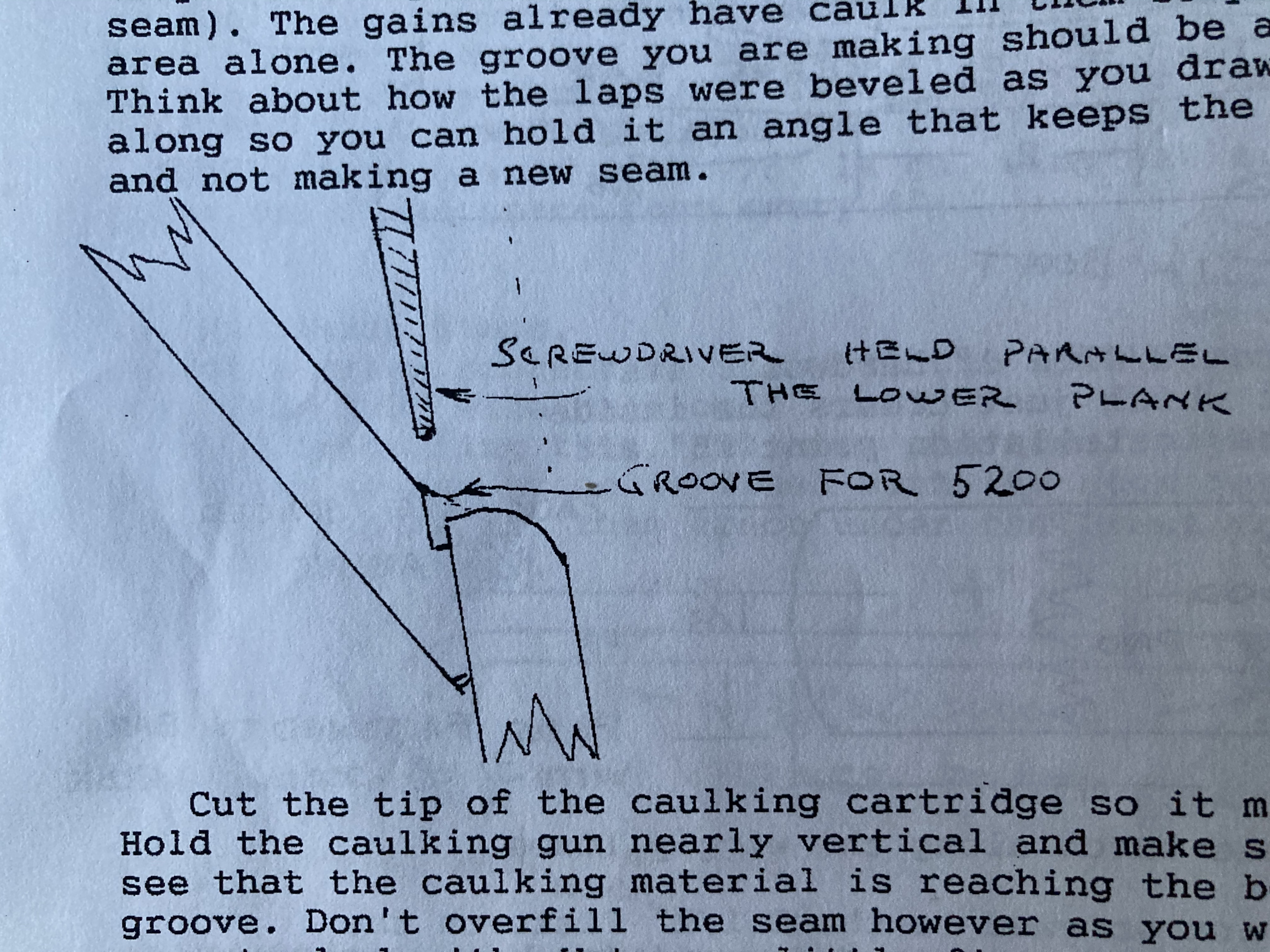

It is really quite simple: After the boat is planked up, cut a shallow groove in the lap seam using a slotted screwdriver. Then put a bead of polyurethane caulk (e.g. Sikaflex 292 or 3M 5200) in the seam and make a nice fillet by running a wetted (rubber-gloved) finger over it.

Image credit: Harry Bryan

Image credit: Harry Bryan

This works on the entire length of the boat, except at the stem (or stems for a double-ender) where the planks are flush, leaving no room for a bead of caulk. So the end(s) of each plank needs to be caulked during the planking, but all the rest can be done after the planking is complete, which will make for a much easier and much cleaner job.

The ends of a Fiddlehead canoe plank joint just before fastening. The white stuff is a bead of Sika 292 sealant.

The ends of a Fiddlehead canoe plank joint just before fastening. The white stuff is a bead of Sika 292 sealant.

These modern polyurethane caulks stick so well and are so flexible that a lapstrake boat treated this way should stay watertight for many years.

- Mikkel Pagh

P.S. Another way of getting a guaranteed watertight lapstrake boat is to build it of glued plywood. This technique works very well but has some drawbacks too.